Download HPLC Column Cleaning & Storage Guide

Topics

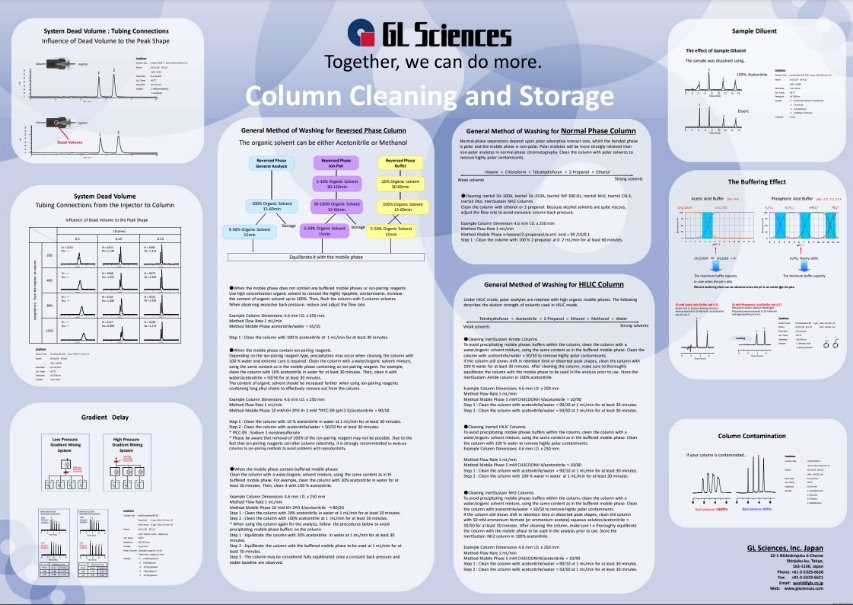

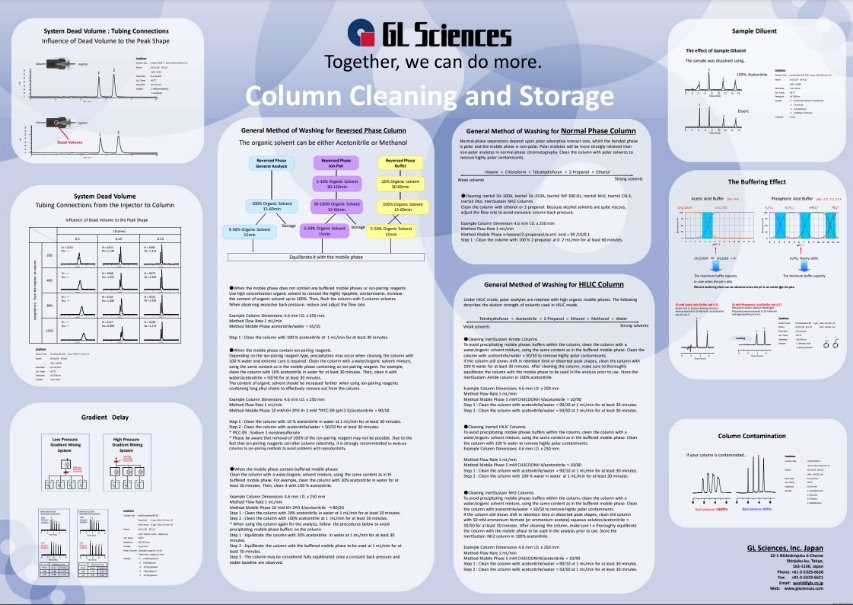

- General method of washing for Reversed Phase Column

- General method of washing for Normal Phased Column

- General method of washing for HILIC Column

Download Column Cleaning & Storage Guide![]()

![]()

Topics

Download Column Cleaning & Storage Guide![]()

![]()

We recommend that you use the HPLC columns that we sell under the following pressures.

Maximum operating pressure of Analytical HPLC Columns

| Analytical Columns | Particle Size | Maximum Operating Pressure (MPa) |

| 1.9 µm, 2 µm | 80 | |

| 3 µm HP | 50 | |

| 3 µm - 10 µm | 20 | |

| Unisil | 5 µm, 10 µm | 20 |

| Titansphere | 5 µm | 20 |

| InertSphere Sugar-1 | 5 µm | 15 |

| InertCore C18 | 2.4 µm | 100 |

| Capillary EX Columns | 3 µm, 5 µm | 20 |

| Capillary EX Nano Columns | 3 µm, 5 µm | 15 |

Maximum operating pressure of Guard Columns

| Guard Columns | Recommended Max. Operating Pressure (MPa) |

| Guard Column for UHPLC | 80 |

Cartridge Guard Column E Cartridge Guard Column Ei GL Cart, Pre-clean ORG PREP Guard Cartridge | 20 |

Packed Guard Columns Packed Mini Guard Columns Capillary Micro Guard Columns Preparative Guard Columns | 20 |

Basic Operating Instructions and Suggested Care of INERTSIL® HPLC Columns

Inertsil® HPLC packings are subject to a rigorous array of QC tests in a ISO 9001 compliant facility, with special emphasis on reagent purity, raw material traceability and consistency in raw materials, and fi nal products. A detailed analysis of all of the physical and chemical properties of Inertsil®, combined with tests for chromatographic selectivity and column packing effi ciency, ensure that each lot of Inertsil® is identical to all previous lots and column-to-column reproducibility is of the highest order. To maintain and maximize peak performance of Inertsil® HPLC columns, and ensure long life and stability of columns please read the following instructions before use.

UNPACKING

Inspect the column upon arrival and contact GL Sciences ([email protected] or 310-265-4424) immediately if you see signs of damage to product or product packaging that may have occured during shipping.

SHIPPING SOLVENTS

Inertsil® columns are shipped with the solvent used for the fi nal QC test of the column, as detailed on the test chromatogram delivered with the column. When preparing to introduce your desired mobile phase into a new column, be aware of the miscibility of the solvents being introduced to the column and the solvent inside the column. If the new eluent being introduced contains buffer sales, it is recommended that the column is fl ushed with a highly aqueous eluent (such as 90:10 Water:MeCN) before introducing buffer, to avoid precipitation of salts on the column. For extra precaution, introduce new buffered eluents WITHOUT the buffer component for 5-10 column volumes, and then switch to the fully buffered eluent composition. Precipitation of buffer salts on the columns is essentially irreversible and destroys the column! When switching between solvents with vastly different polarities, it may be necessary to fi rst purge the column with a mutually miscible solvent such as Isopropyl Alcohol or Dioxane at a reduced fl ow rate (approximately 50% of normal). Flushing with a minimum of 5 column volumes is recommended ( e.g. 10 mL for a 150 x 4.6mm I.D. column).

Note: With Inertsil® SIL-100A, it is time consuming to fl ush the buffer or water in the pores of the packing after using reversed-phase eluent. In fact, it is nearly impossible to remove water from the surface of a silica column and once water adsorbs on the surface, the selectivity of the column is subsequently altered. (If a subsequent analysis in the normal phase mode is performed, and the fl ush has not been thoroughly completed, the elution order and retention time may vary signifi cantly). Therefore this type of column should be used solely for one type of analysis (basically, normal phase. If you want to use reverse phase on a polar column, we recommend CN, Diol, or Amino.

COLUMN CARE

Do not drop or bump columns, as this can fracture the uniformity of the bed and result in tailing or split peaks.

Eluent pH - GL Sciences’ InertSustain® HPLC columns are designed for use between pH 1.5 and 10.0, and have known to provide good stability even at pH approaching 11. Other Inertsil® columns, such as ODS-2, ODS-3, and ODS-4 provide optimum lifetime when used with eluents within the pH range of 2.0 to < 8. At pH above 8, silica gels begin to dissolve; at acidic pH below 2.0 certain bonded phases (particularly CN) become hydrolyzed and gradual loss of bonded phase can occur. While many customers use the columns outside both sides of the pH spectrum with excellent results and good column lifetime, the best lifetimes are usually obtained at intermediate pH conditions. One benefi t of Inertsil’s extreme base deactivation is the ability to analyze highly polar compounds at their pKa without peak tailing.

Pressure - To maximize column life operate at pressures up to 20 MPa (~ 3000 psi) for standard HPLC phases (UHPLC columns can be used at higher pressures, as indicated on the test chromatogram). Column Temperature - To maximize column lifetime, limit column temperature to 60C. Sample Dissolution - Samples should be dissolved in the eluent or solvent weaker than the eluent, which helps avoid sample precipitation at the column head and inconsistent retention values. Filter sample with 0.45μ membrane to remove particulate matter before injection. Solvents - Use HPLC or spectroscopy grade solvents that have been fi ltered through a 0.45μ fi lter. Filter all buffer solutions before use. Avoid introduction of particulates onto the column at all costs.

Column Temperature - To maximize column lifetime, limit column temperature to 60C.

Sample Dissolution - Samples should be dissolved in the eluent or solvent weaker than the eluent, which helps avoid sample precipitation at the column head and inconsistent retention values. Filter sample with 0.45μ membrane to remove particulate matter before injection.

Solvents - Use HPLC or spectroscopy grade solvents that have been fi ltered through a 0.45μ fi lter. Filter all buffer solutions before use. Avoid introduction of particulates onto the column at all costs

COLUMN PROTECTION

Installation of a GL Sciences’ Preclean ORG guard cartridge between the pump and the injector removes organic contamination from aqueous eluent. Guard columns also help protect more valuable analytical columns by binding non-eluting sample components before the analytical column becomes contaminated.

STORAGE OF COLUMNS

After using the column with eluent containing buffer or ion-pair reagent, wash the column completely with a saltfree eluent before storing. When storing the column for a long period, store it in 100% organic solvent. MeCN is the most commonly used solvent, though isopropyl alcohol and MeOH are also commonly used. Seal the column with the plugs provided and store it in a location with a stable temperature. Inertsil® columns are manufactured, inspected, packaged and shipped under strict standards of quality control. Should you fi nd any defect in performance, please contact your GL Sciences’ provider, who will ensure your complete satisfaction. We regret, however, that we cannot guarantee the lifetime of columns, nor can we accept any claim when their performance has deteriorated due to no-compliance with the above operating instructions or as a result of normal aging.

COMMON PROBLEMS TO AVOID AT INSTALLATION

If there are tailing peaks early in the elution, the cause is probably dead volume, most commonly caused by a pore fi tting connection between the injector and column. Check that the connecting supply line is properly inserted all the way into the column joint. Piping to the injector and to the detector should be as short and have as small an inside diameter as possible. Sub-optimum connections and plumbing have increasing negative effects as the column diameter is decreased.

Baseline drift and noise can be caused by defective pump operation due to air bubbles, reduction of light intensity when using a UV detector. Bubbles often occur during high temperature analysis or the when there are problems with solvent purity.

The most common cause of column back pressure increases or double peaks is blockage of the inlet frit by sample particulates - either from the analyte/matrix or particles created by aging pump seals - or large quantities of lipophilic compounds adsorbing to the head of the column. Pass the eluent through a 0.45μ membrane fi lter before use. The column can also be protected from contamination by using a guard column / cartridge.

| Type | Principal Columns | Shipping Solvnet |

| Normal-Phase | CN-3, NH2, Diol, Silica | n-hexane:Ethanol |

| Reverse-Phase | ODS, C8, Phenyl, C4, | MeCN:Water or MeOH:Water |

| Ion-Exchange | SAX, SCX | Methanol (100%) |

Thank you for purchasing an InertSustain & Inertsil series column.

InertSustain and Inertsil series packing materials are subjected to a rigourous array of QC test in our ISO9001 compliant facility, with special emphasis on reagent purity, consistency and traceability in raw materials, and final products. A detailed analysis of the physical and chemical properties of InertSustain and Inertsil series columns, combined with tests for chromatogaphic sensitivity and column packing material efficiency, ensure that each lot of InertSustain and Inertsil series columns are identical to all previous lots, and column-to-column reproducibilty is of the highest order.

To maintain and maximize peak performance of InertSustain and Inertsil series columns, and to ensure long life and stability of your column please read the following instructions before use.

Download InertSustain/ Inertsil Series Care & Use Manual